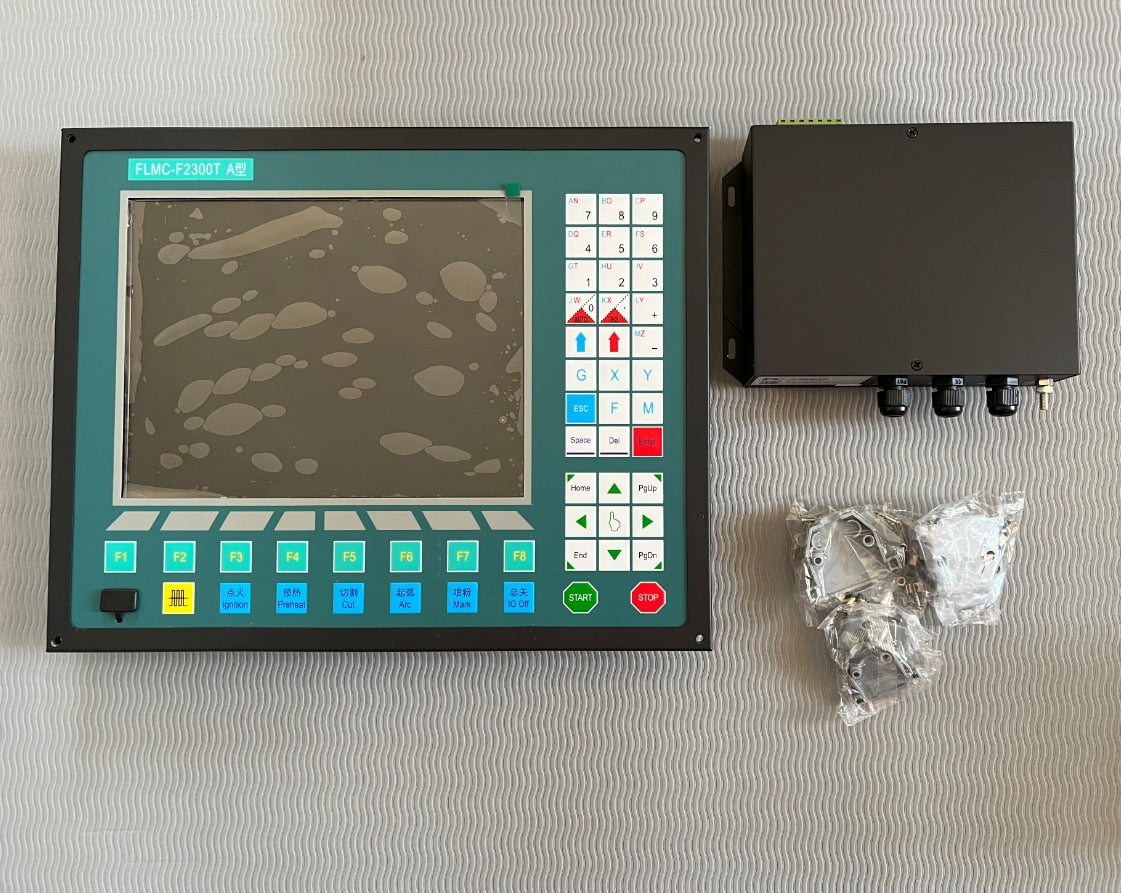

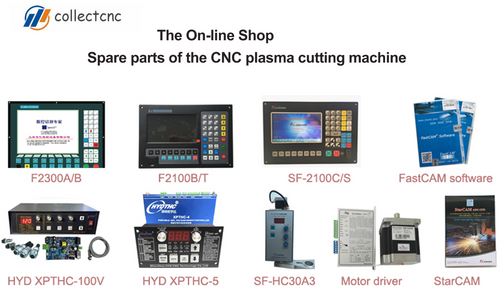

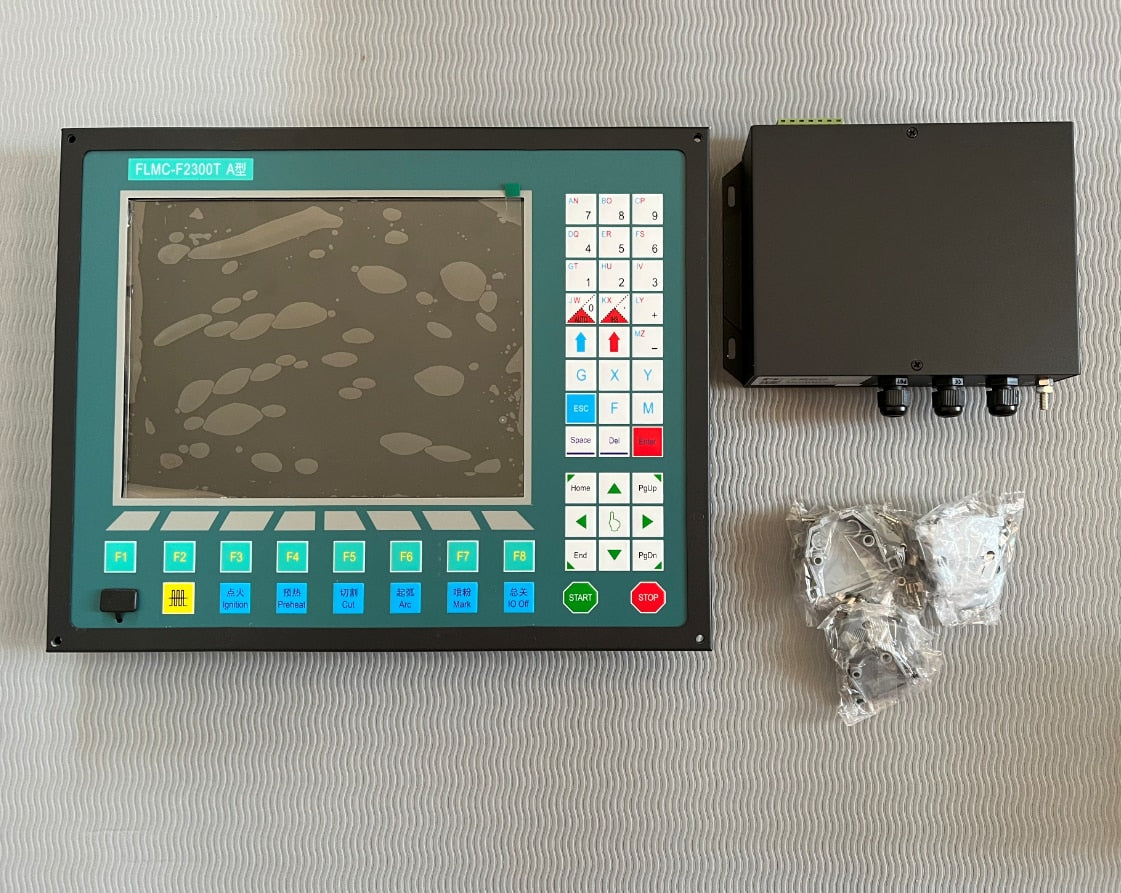

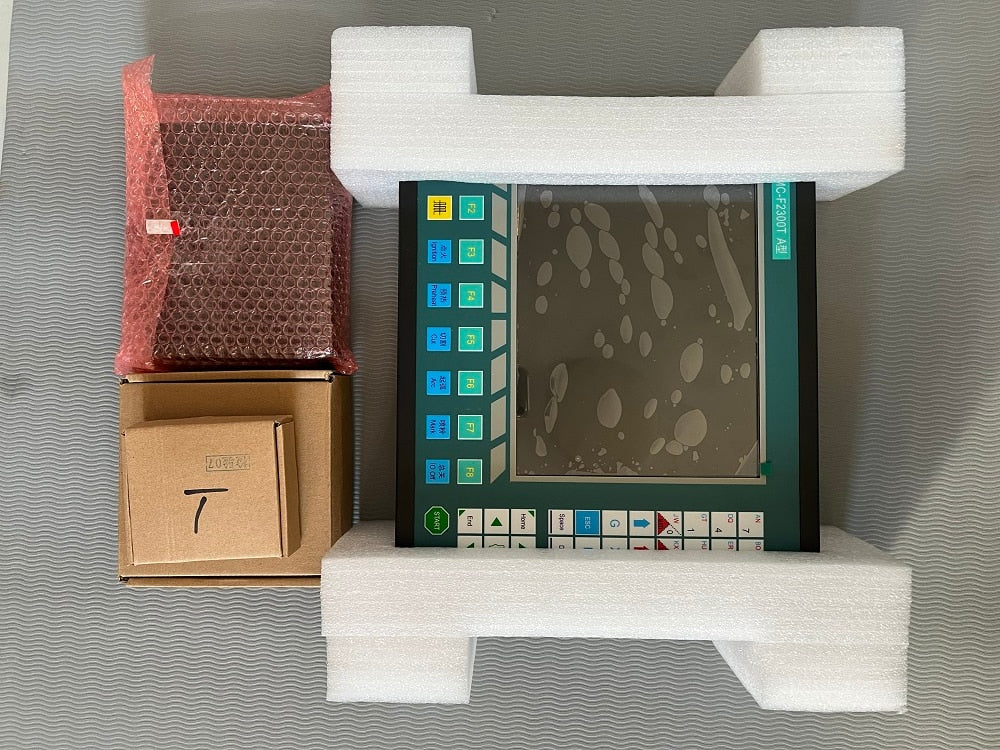

F2300AT Controller for CNC Plasma and Flame Cutting Machine

F2300AT Controller for CNC Plasma and Flame Cutting Machine

Couldn't load pickup availability

F2300AT CNC controller

Order details

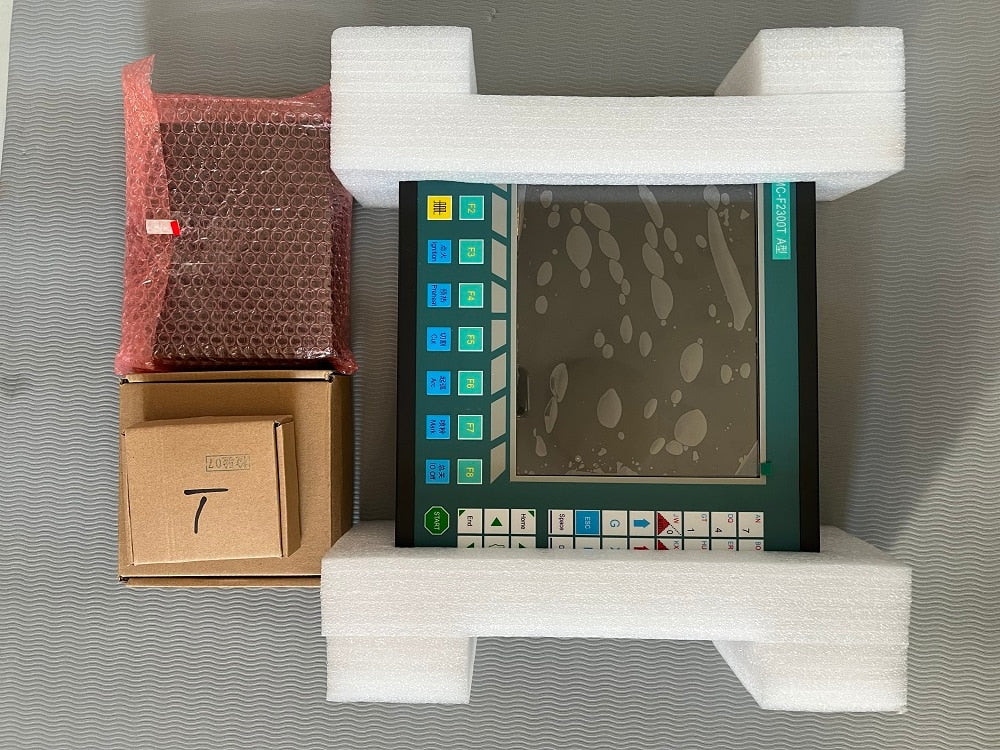

1. 2300AT 1PC

lWorking Temperature, 0℃~50℃. Relative Humidity, 5~95%.

lOperation Voltage:

DC +24V.

lThe controller

should be installed in a cab which can provide protection from powder.

lThe

controller would be better used in the situation without high voltage radiation.

Maintenance

lKEEP HANDS CLEAR of dangerous moving machinery.

All control action, including manual action, can be executed using the front

panel keys or remote interface.

lLoose fitting clothing or ties may become

entangled in the machinery. These items should not be worn while operating the

machine.

lThis controller should only be operated by

trained service person.

lDo not open the controller unless obtaining the authorization.

lDo not let any acid, alkaline, corrosive and

other items to corrode the controller.

High Voltages

lElectric shock can kill. Be sure this equipment is safely installed in accordance with

enclosed procedures and specifications.

lAvoid contact with electrical wires and cabling while power is on.

lOnly trained person can operate this controller.

This controller is very light and handy and it is very easy to operate. The

controller provides menu or illustration for all the operations for the convenience

of users. All key switches are human oriented designed, and they are very

convenient and comfortable.

The controller high performance

ARM chip and ultra large scale programmable device FPGA, runs multi task

real-time operating system and adopts the method of combining software

interpolation with hardware interpolation, making high-speed operation more

stable and reliable. Reflect speed is very fast. Based on Fangling's research

of CNC system for many years, the machines control is more stable and the

protection mechanism is quite good.

1. Characteristics

1)Chinese/English/French/Portuguese/Russian/Denmark/Korean

language are supported, the language can be switched easily. In addition to

Chinese and English, it need customer to provide language translation

documents. In addition to Arabic, other languages are all available.

2)49 categories different graphics (including grid pattern), chip part and hole part are

alternative.

3)Support the EIA code (G code) and various CAM software , such as FastCAM, FreeNest, SmartNest, IBE.

Support G code with suffix such as TXT, CNC, NC, MPG, B3.

4)Compact keyboard design and easy to input files.

5)Shape have some operations such as Proportion, Rotate, and Mirror.

6)Shape can be arrayed in matrix, interaction, stacked modes.

7)Steel plate can be adjusted according to any steel side.

8)Coordinate system can be customized to support the two dimensional coordinates of all eight kinds.

9)All input and output port type and the number can be customized (normally open or normally

closed).

10)Self-diagnostic function, to diagnose the key status and all the IO status, facilitate inspection and debug.

11)Provide a front USB interface for copying files.

12)System can be upgraded by USB interface easily, and we provide lifetime upgrade service.

13)All functions and techniques can upgrade online and don’t worry about the after sale service.

14)Import and export files by single or all files.

2 Technical Indicator

1)Control Axis: 2 axis linkage(3 axis customizable)

2)Control accuracy: +/-0.001mm

3)Coordinate range: +/- 99999.99mm

4)Max pulses: 200 kHz.Max speed: 15,000 mm/m

5)Max lines of code: 80,000lines

6)Max size of single code file: 4M

7)Time resolution: 10ms

8)Working Voltage: DC +24V

direct-current power input, power > 80W.

9)Working Temperature: -10℃~+60℃. Relative Humidity, 0~95%.

10)Max power of drive arc THC motor: 45W (suitable for models with “T”). if need more power,

can select maximum value: 200W.